Staying below 1.5° C

requires that we

— take carbon out of the air

— stop putting carbon into the air

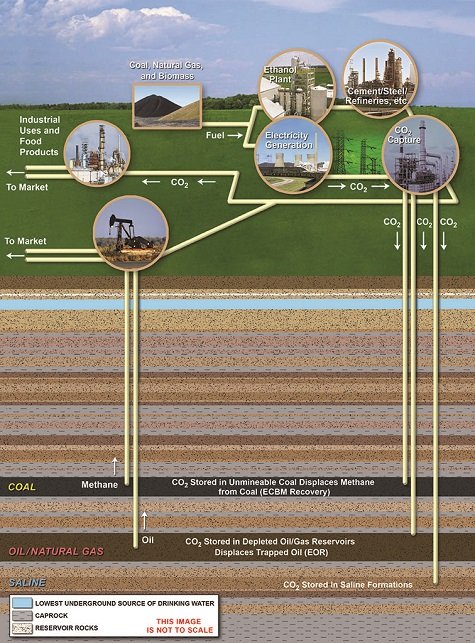

Existing Carbon Capture and Use Systems (CCUS) systems focus on capturing emissions as they happen and preventing the CO2 from escaping.

This is a strategy to stop or slow down putting carbon into the air from high-emissions sources such as

- oil refineries,

- power stations, and

- cement factories.

This strategy does not take the existing carbon overload out of the air.

Currently, CCUS systems capture about 0.1% of global GHG emission per year. That’s only about 6.4 hours worth of worldwide GHG emissions.

The latest projection for total global CCUS capacity by 2030 jumps to just under 37 hours of GHG emissions per year. Even though this is a projected six-fold increase, it still only amounts to a day and a half of the annual worldwide emissions.

More disappointing than the limited amount of carbon capture is CCUS’ carbon endpoint.

BloombergNEF projects that by 2030 two thirds of the captured atmospheric carbon will be buried underground. In other words, treating carbon as a waste to be dumped somewhere and hoping it will never find its way to the surface.

The Algae Biomass + HydroCarbon Splitter™ Alternative

The power of photosynthesis in rapid-growth microalgae is the key to scalable atmospheric drawdown of CO2. Carbon dioxide (CO2) and water (H2O) are re-combined into a carbohydrate plus oxygen by the algae.

Algae biomass is harvested regularly. It is processed through an anaerobic digester and then through hydrocarbon splitting to produce

- hydrogen gas,

- carbon allotropes,

- soil enriching minerals, and

- electricity.

The entire process is run on renewable, zero-emissions energy.

Every component of the algae-biomass harvest is a useful product.

Algae Biomass + HydroCarbon Splitting (AB+HCS) is profitable.

It converts CCUS from a necessary but costly burden

into a self-sustaining and lucrative business.

Anaerob-Electrolyzer-HCS-test-bed

Algae Biomass system + HydroCarbon Splitting test bed

Algae farms need not compete with food or water needs.

The algae can grow on non-arable land or at sea,

using non-potable water from saline aquifers

and ocean waters.

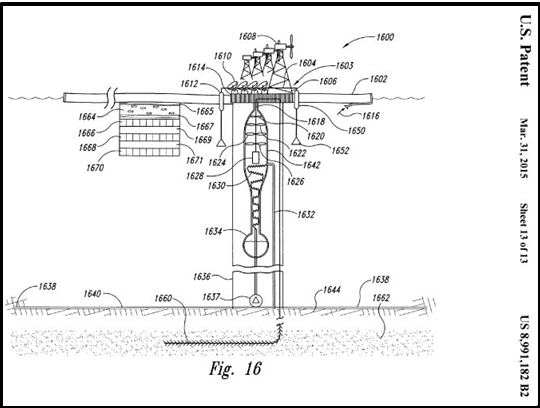

McAlister SOTEC (solar ocean thermal energy conversion) installations improve efficiency in energy production and create ideal thermal growing zones for algae-biomass production.

The schematic above is from one of several McAlister SOTEC patents.

This USGS map of saline aquifers in the US illustrates the untapped non-potable water resources available to support algae farming without competing for water with food production farms or human water consumption.

The Sustainable

Algae Biomass

Economic Model

Hydrogen-based Technology Breakthroughs

HydroCarbon Splitting

This breakthrough technology pre-emptively separates hydrogen from carbon in all types of hydrocarbon feedstocks

- biomass,

- biowaste, and

- fossil fuel.

Harvested Carbon

Carbon that is pre-emptively harvested from biomass, biowaste, and even fossil feedstocks transforms from a dangerous waste to a valuable asset.

Clean Air Injector-Igniter

Combustion engines retrofit with this smart fuel injection system run emissions-free on net-hydrogen fuel.

Hydrogen Fuel

This revolutionary

net-hydrogen fuel is liquid

at room temperature and pressure. It is a renewable, sustainable zero-carbon energy carrier.

Algae CO2 Drawdown

Rapid-growth microalgae draws down atmospheric CO2 at the rate of 2.7 tons per acre per day. Using algae as a biomass feedstock co-harvests carbon and hydrogen in a renewable, zero-carbon emissions process.