Clean Air Injector-Igniters

Convert Combustion Engines and Devices

to Zero-Emissions Hydrogen Fuel

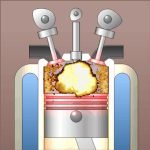

DIESEL: This typical diesel combustion chamber operates at high heat. The high temperature required for combustion creates oxides of nitrogen (NOx). The burning liquid diesel fuel sprayed on the chamber walls during fuel injection causes

- carbon soot etching of the chamber walls and

- sludge in the engine oil.

Carbon soot, CO2, and NOx are emitted in the exhaust.

HYDROGEN PLASMA: The same combustion chamber has been retrofitted with the clean air injector-igniter. The controlled hydrogen plasma injection focuses the combustion event inside an envelope of insulating air. It runs much cooler, staying below the heat threshold to generate NOx.

Also

- no carbon soot and

- less engine wear.

Only clean air and water vapor are emitted in the exhaust.

The paradigm shift to clean, renewable fuels requires

new technologies such as electric vehicles

combined with

new approaches to existing technologies,

particularly combustion engines.

Combustion engines can be retrofitted to run clean and emissions-free for a fraction of the cost of junking and replacing them.

- Lawnmowers, go-carts, scooters, and motorcycles.

- Trucks, trains, ships, and planes.

- Home backup generators, schools, hospitals, and regional power stations.

- Industrial boilers, furnaces, and burners.

We can’t realistically throw away the world’s nearly 2.5 billion still-productive transportation engines to replace them all with electric vehicles. Waste of that magnitude would be unmanageable. The replacement cost is unaffordable to a significant percentage of the world’s communities.

Nor can we expect to discard the additional 2-plus billion power generators, industrial furnaces, boilers, and other combustion devices currently running on fossil fuel. But we can give new Zero-Emissions life to the installed asset base of current combustion engines by retrofitting them to run on hydrogen fuel.

SmartPlug™ Stratified Hydrogen Combustion can actually clean the air during operation of piston engines, gas turbines, furnaces, and boilers.

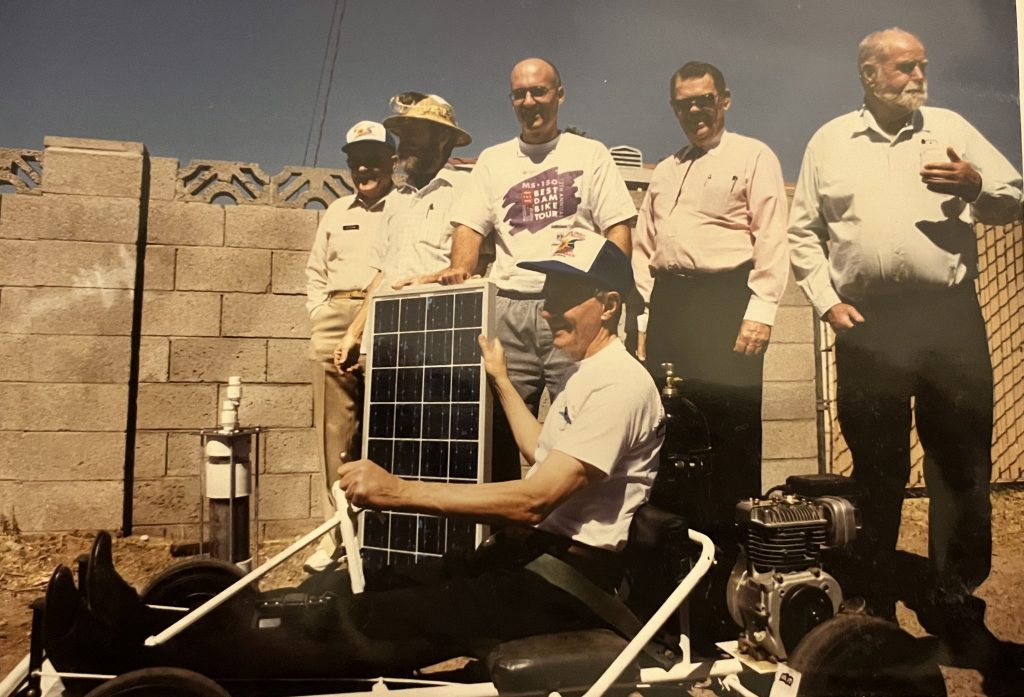

The Hydrogen Association began demonstrating

the feasibility of hydrogen-fueled engines long before

the World’s First Clean Fuel Go-Cart Race in April 1999.

Note the solar energy panel beside the driver and the black carbon-wrapped hydrogen

fuel tank between the back of his seat and the engine.

Hydrogen-based Technology Breakthroughs

HydroCarbon Splitting

This breakthrough technology pre-emptively separates hydrogen from carbon in all types of hydrocarbon feedstocks

- biomass,

- biowaste, and

- fossil fuel.

Harvested Carbon

Carbon that is pre-emptively harvested from biomass, biowaste, and even fossil feedstocks transforms from a dangerous waste to a valuable asset.

Clean Air Injector-Igniter

Combustion engines retrofit with this smart fuel injection system run emissions-free on net-hydrogen fuel.

Hydrogen Fuel

This revolutionary

net-hydrogen fuel is liquid

at room temperature and pressure. It is a renewable, sustainable zero-carbon energy carrier.

Algae CO2 Drawdown

Rapid-growth microalgae draws down atmospheric CO2 at the rate of 2.7 tons per acre per day. Using algae as a biomass feedstock co-harvests carbon and hydrogen in a renewable, zero-carbon emissions process.

Partner Resources

Helpful Links